|

Can you imagine a thread which has five times the strength of steel (even

though

its density is six times less) and is twice as elastic as nylon? This thread, which is extremely difficult for man to manufacture, is the silk produced by the spiders we find in our gardens. These little creatures known by the charming name of Oribitelous, or geometric spiders, have nine silk-producing glands situated in the stomach and they can produce different types of silk according to need (for the cocoon, or for spinning the web).You can discover more about the various peculiarities and beautiful colours of different types of spider on the internet. I find these geometric webs beside rivers and if possible choose large ones which are not damp. The fineness, flexibility, elasticity and strength make for a promising textile - in fact it is estimated that this fibre can support more than 450kgs per mm2.

Studies carried out by Dr Turner, president of Bexia Biotechnologies (Canada) underline the scientific investigations on spiders and their silk: "It

is incredible that such a small creature which we find in our gardens

can

create

such an amazing material thanks to amino acids, the same elements

which

form skin and hair. Spiders' silk is a scientific marvel, a structure

of

nano fibres, ready-assembled, biodegradable, with a high performance, Spiders' silk could have numerous applications in various domains:

Even finer fibre-optics, thanks to spiders' silk! Scientists use these silken threads as a support for silicate, and after heat treatment the silk disappears leaving a fibre optic tube of only 2 nanometres in diametre.

Could man master the fabrication of synthetic

spider's silk? That is still to

be discovered. Meanwhile,

after several years of research on genetic manipulation,

Canadian scientists

have been able to introduce the silk gene into the genetic

code of goats.

A litre of milk will contain about 20 grams of spiders' silk

protein. There

remains the stage of spinning, but the subject is very

difficult and

solutions to the problem are secret. In

Germany researchers are interested in the tobacco plant, and again by

gene manipulation,

the plant will produce in its leaves a few milligrams of protein

of spiders' silk.We have not yet reached the industrialisation stage,

but for how long? |

A fabric in winter

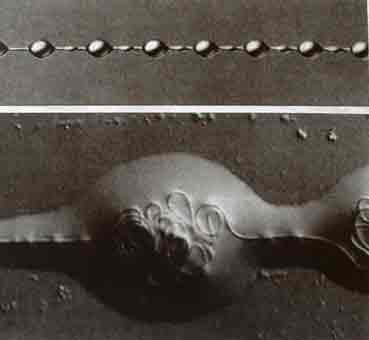

Trapping thread of Ecribellate, the garden spider. Enlarging 10 times. Note that the central fibre winds into a ball which lengthens where necessary.

|

|